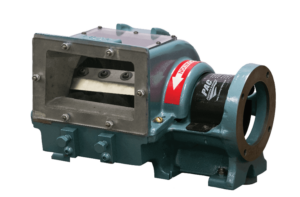

Cutters & Granulators

PAC’s cutters and granulators are the best in the industry

PAC’s durable cutters and granulators are the high-performance foundation of our automated inline cutter/fan-based trim and matrix waste handling systems. Our cutters and granulators can handle almost any material safely, effectively and quietly. Ultra-thin film, sheet, PSA trim and matrix, foil, laminate, paper, nonwovens, corrugated material and fabric – even carpeting and automotive floor mat trim – are no match for the precision chopping of our advanced cutters and granulators.

For our service/maintenance page, please click the button below.

Click HereGranulation Screen

PAC’s granulators feature 180-degree screens with holes ranging from 0.125 to 2.0 inches in diameter. Custom sizes are also available. Throughputs may exceed 400 pounds per hour depending on the screen. Screens are easily removed for maintenance.

The PAC 78 Series inline cutters and granulators are ideal for materials conveyed in ducts up to six inches in diameter. The PAC 811 Series excels with larger volumes and heavier materials.

PAC cutters and granulators can feature either rear or bottom discharges, and may be installed new or retrofitted onto existing systems.

10,000 Installations Worldwide

Boasting more than 10,000 installations worldwide, PAC simply offers the best cutters and granulators in the industry. PAC’s 78 Series and 811 Series inline cutters and granulators feature a host of engineering advances that ensure fast, clog-free handling of trim, matrix and filament waste.

The competition just can’t cut it

There are more Precision AirConvey cutters installed than all other brands combined

Superior design and high-performance components make PAC cutters #1. See for yourself why PAC is the smart choice.

Shaftless cutting chamber & open box rotor: For free passage of air and smooth quiet cutting at consistent pressure.

Cylindrically ground, rotating fly knives: Our sharpening techniques ensure accuracy and tight clearances. Proprietary milling processes match fly knives to rotor notches for secure, positive location and retention.

Two- or six-knife designs: AISI-D2 tool steel, in optional CPM (A8) or tungsten carbide, to cut film to .0005″ with a controlled knife clearance of .00025″.

Removable aluminum top cover: Safe and easy access to the cutting chamber for maintenance.

Angled cutter: Reduces sound significantly and provides shock-free, low-noise shear cutting.

High-precision ABEC-7 bearings: Our outboard sealed bearing design prevents waste material contamination from contact with lubricants or other substances. The world’s best ball bearings give PAC cutters the tightest fly to bed knife clearance.

Compact space-saving design: A flange-mounted motor and low profile ease installation and eliminate the need for a bulky separate base.